GORE® DVI Cables (Digital Only) for Defense Aircraft

These versatile single-link cables are adequately crafted for the digital component of DVI systems and fit effortlessly into standard harness designs. Compact and robust, they meet stringent aviation requirements and reliably support high-resolution aircraft displays in demanding radar environments.

연락처

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Optimal Viewing On Displays

Engineers have often told us that it’s challenging designing aircraft harnesses with digital components in DVI (digital video interface) systems that can reliably stand up to demanding radar environments.

Gore offers a single-link cable solution designed specifically for the digital component of DVI systems that the military can always trust and rely on during missions.

GORE DVI Cables (Digital Only) are proven to deliver exceptional signal quality and high data rate video transmission in demanding EMI (electromagnetic interference) environments. They also support the highest video resolution for optimal viewing on aircraft cockpit and workstation displays. Unlike many substitutes, they meet rigorous military aerospace standards for impedance control, insertion loss, skew and EMI shielding necessary for stable performance in DVI systems.

Easy Fit into Standard Harness Designs

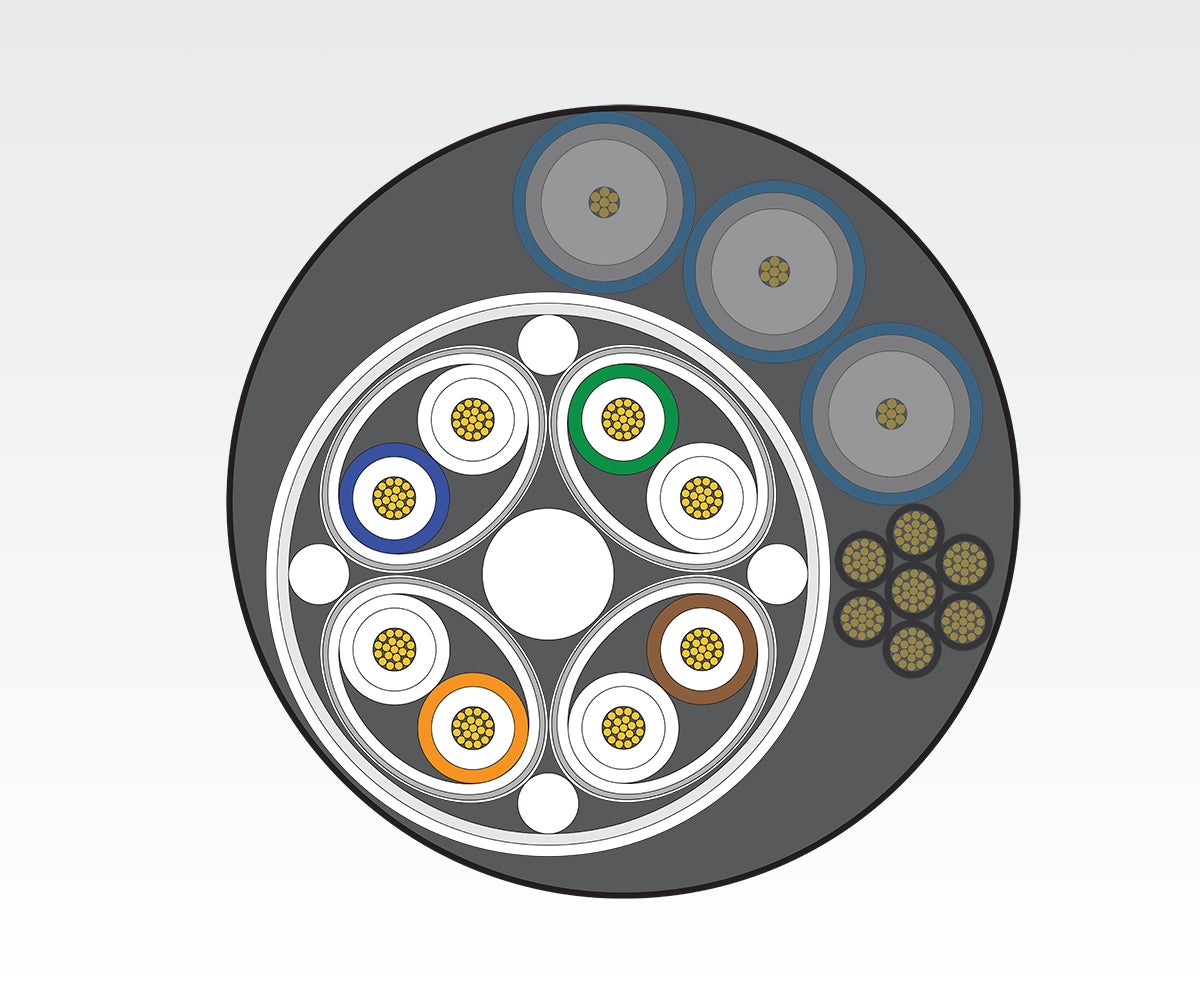

Standard harness cross-section with GORE DVI Cables (Digital Only)

Our single-link cables make it easier for design engineers to use them in standard DVI harnesses. They’re smaller, lighter and more flexible without sacrificing durability compared to substitutes. They fit easily into a harness cross-section with other components without getting damaged or breaking, saving you time and money on cable replacements.

Applications

Designed specifically for standard harnesses with digital components, GORE DVI Cables (Digital Only) provide satisfactory results in airborne applications, like:

- cockpit displays

- aircrew workstation displays

- mission systems

- weather mapping

Our cables can also be terminated with a variety of leading high-speed aerospace connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 contacts.

Features & Benefits

Unlike industry substitutes, GORE DVI Cables (Digital Only) are built with extremely durable materials proven to defend against complex maintenance and operational conditions, including:

- single-link DVI digital component design

- temperature- and abrasion-resistant materials

- chemically inert, EMI shielding materials

- lightweight with smaller diameters

To system architects and engineers, our reliable cables offer a host of benefits that improve their overall performance in defense aircraft, like:

- exceptional signal quality for high-speed video transfer

- support highest video resolution for optimal viewing on displays

- meet requirements for impedance control, insertion loss, skew, EMI shielding

- robust protection and stable performance in demanding radar environments

- easy fit into standard DVI harnesses with small, lightweight, flexible construction

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE DVI Cables (Digital Only) for defense aircraft. Download our data sheet for more cable characteristics, performance data, qualifications and part number. Also, fill out a short form for instant access to the drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | <15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft.) | 40.0 (12.0) |

| Maximum Skew ps/m (ps/ft.) Pair-to-Pair Within Pair | 52.50 (16.0) 13.12 (4.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/White, Brown/White, Green/White, Orange/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Get Samples or Buy

Choosing GORE DVI Cables (Digital Only) means you no longer have to worry about designing harnesses with digital components that are inadequate for radar environments. Order a complimentary sample of our pre-qualified cable to evaluate its quality and compatibility with your defense aircraft harness configuration.

If you’re ready to buy now, connect with an approved distributor for in-stock availability. Or, call us today to talk about your specific needs and requirements.

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets, 12.79 MB

View all resources for GORE DVI Cables (Digital Only) for Defense Aircraft

최신 뉴스

Gore가 10월 20일부터 10월 23일까지 KINTEX에서 진행되는 Seoul ADEX 2025에 참가합니다. 수십 년간 군수 산업에서 신뢰받아 온 기술력을 기반으로, 임무 성공과 생존성, 안전성을 보장하는 혁신적인 Gore의 솔루션을 확인하실 수 있습니다.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

관련 제품

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- Fibre Channel Cables for Defense Aircraft

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- Fiber Optic Cables for Defense Air & Land

- MIL-STD-1760 Assemblies for Defense Aircraft

- Cable Protection Systems for Defense Aircraft

- Abrasion Resistant Cable Jacket for Defense Aircraft

팔로우: GORE® DVI Cables (Digital Only) for Defense Aircraft