GORE® CAN Bus Cables for Civil Aircraft

Our controlled-impedance cables meet the industry’s need for faster data rates in next-gen avionics and IFEC systems. Compact and flexible, they save weight while offering an inverted dielectric design that makes wire prep and installation easier. Gore’s reliable cables ensure a more connected, safe and successful flight every time.

연락처

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

HIGH-QUALITY SIGNALS

Cables are a key component of critical avionics. They must be able to transmit data and video in cockpit and IFEC systems as fast as possible, reliably and accurately, no matter the circumstances to ensure a successful flight and passenger experience.

Controlled-impedance GORE CAN Bus Cables enable high-quality signals for high data rate transmission up to 1 GHz, whatever conditions the aircraft encounters. The reason is our innovative cable technology that provides versatile protection to effectively shield wires from extreme impact. Our cables withstand the mechanical, electrical, and environmental stress of flight operations — like rapid temperature changes, harsh contaminants, repeated vibration, and rigorous routing in airframes.

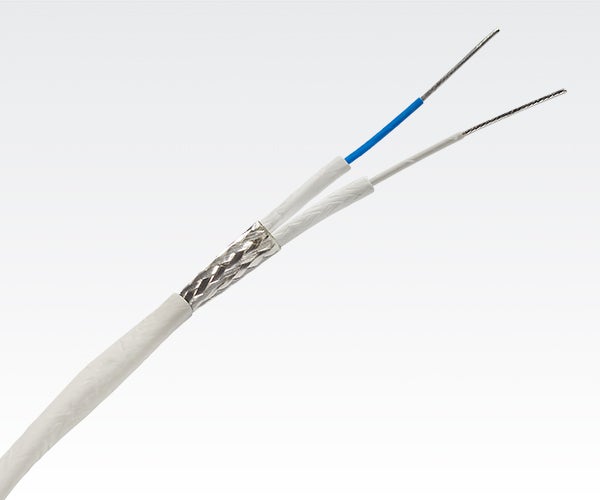

Fast & Trouble-Free Routing

Our cables are 40% smaller than alternative designs, which makes them lighter weight. A smaller diameter also means increased flexibility with a tight bend radius for quick routing and installation without any trouble. Maintainers will also like that our cables have a unique inverted dielectric, which means easier wire preparation and insertion in smaller connector systems.

Compact, lightweight footprint of GORE CAN Bus Cables.

Applications

GORE CAN Bus Cables are suitable for today’s faster avionics digital networks and other applications requiring secure, constant high data rate transfer, like:

- avionics digital networks

- cabin management systems

- controller area networks

- data links

- electronic diagnostics

- HD streaming video systems

- serial buses

Our cables can also be terminated with a variety of leading high-speed aerospace connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 and 22D contacts.

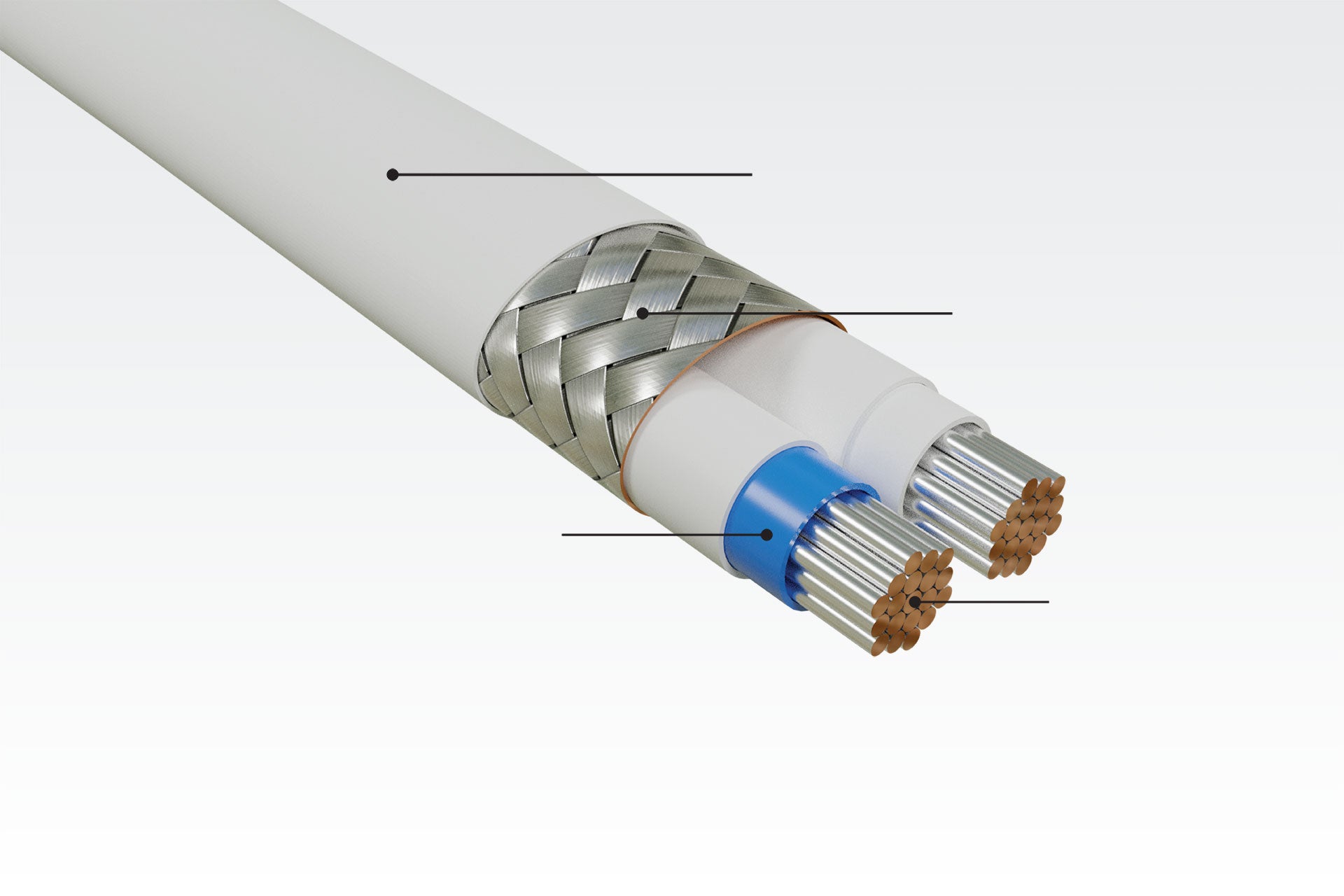

Features & Benefits

GORE CAN Bus Cables are engineered with unique features that make them more durable against challenging environmental factors and aircraft conditions, including:

- inverted dielectric design with smaller diameters

- temperature- and abrasion-resistant materials

- chemically inert materials

These aviation cables provide system architects and engineers with many benefits that improve their overall performance in civil aircraft, like:

- high-quality signals for fast, secure data transmission up to 1 GHz

- proven controlled impedance at 120 ohms

- versatile protection against extreme mechanical/environmental impact

- size and weight savings with 40% smaller diameters than alternative designs

- trouble-free routing with improved flexibility and reduced bend radius

- easier wire prep and insertion in smaller connector systems

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawings

These values demonstrate the electrical, mechanical and environmental performance of GORE CAN Bus Cables for civil aircraft. Download our data sheet for more cable characteristics, qualifications and part numbers. Also, fill out a short form for instant access to drawings.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 120 ± 10 |

| Typical Operating Voltage V | <15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 42.0 (12.8) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Blue/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Get Samples or Buy

When put to the test, GORE CAN Bus cables maintain stable communications, keep passengers connected and stream constant IFE on avionics digital networks. Find out if our controlled-impedance cable with an inverted dielectric is the right fit for your application by ordering our selected pre-qualified samples, which are complimentary.

To find out more or discuss your specific characteristic limits and civil aircraft application needs, contact us today. Or, contact one of our authorized distributors when you’re ready to place an order.

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets, 12.79 MB

View all resources for GORE CAN Bus Cables for Civil Aircraft

최신 뉴스

Gore가 10월 20일부터 10월 23일까지 KINTEX에서 진행되는 Seoul ADEX 2025에 참가합니다. 수십 년간 군수 산업에서 신뢰받아 온 기술력을 기반으로, 임무 성공과 생존성, 안전성을 보장하는 혁신적인 Gore의 솔루션을 확인하실 수 있습니다.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

관련 제품

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Civil Aircraft

- Ethernet Cables for Civil Aircraft

- Quad Cables for Civil Aircraft

- FireWire® Cables for Civil Aircraft

- Fibre Channel Cables for Civil Aircraft

- USB Cables for Civil Aircraft

- HDMI Cables for Civil Aircraft

- DVI Cables (Digital Only) for Civil Aircraft

- Fiber Optic Cables for Civil Aircraft

- Cable Protection Systems for Civil Aircraft

- Abrasion Resistant Cable Jacket for Civil Aircraft

팔로우: GORE® CAN Bus Cables for Civil Aircraft