GORE® PHASEFLEX® Microwave/RF Test Assemblies, 110 GHz

Gore offers a rugged, lightweight 110 GHz test assembly that optimizes the performance of test systems while reducing the total cost of test and ownership over time. Our assemblies provide reliable electrical performance with flexure and temperature in demanding environments.

연락처

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

A recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance over time.

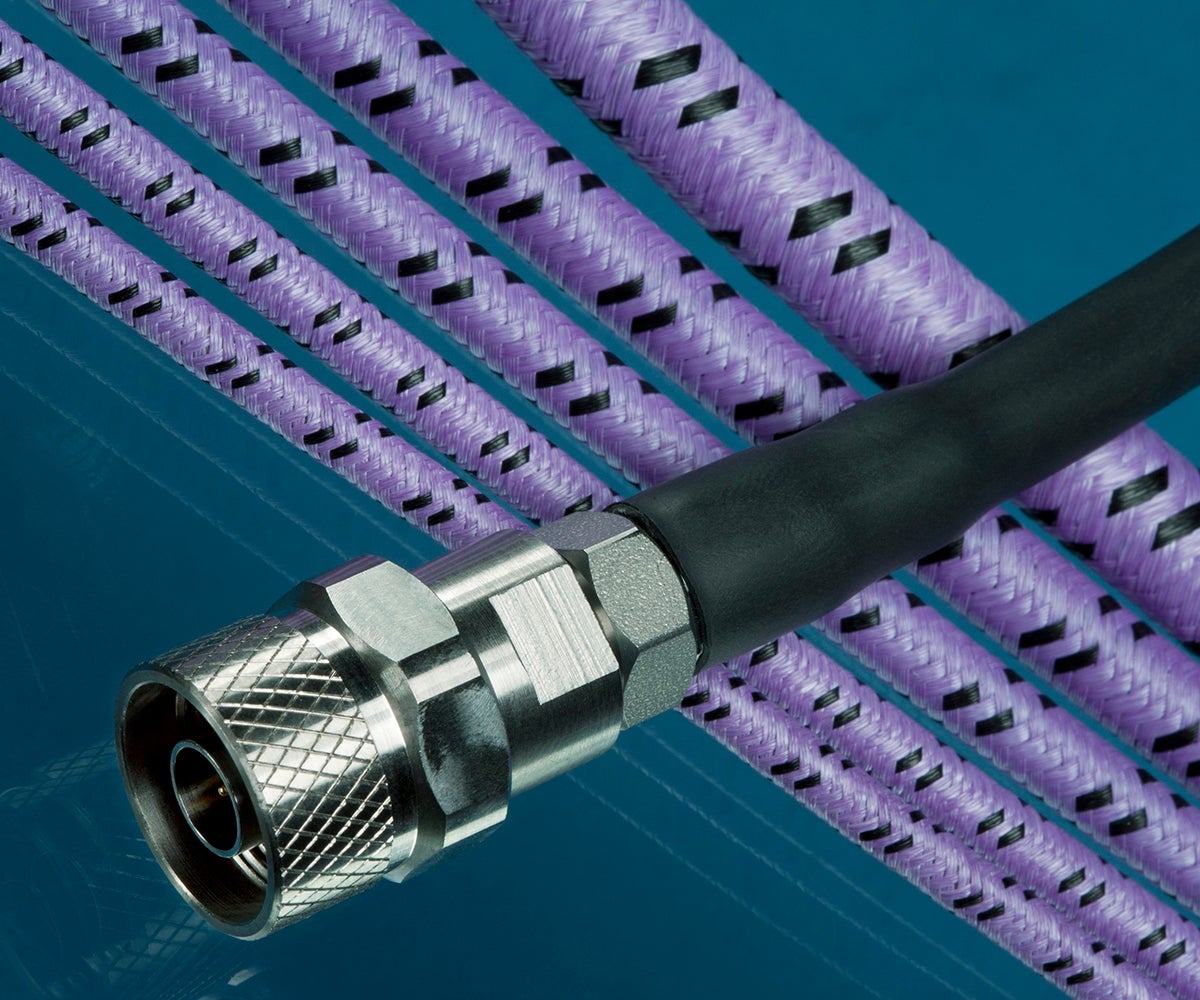

Rugged Construction Delivers Longer Service Life

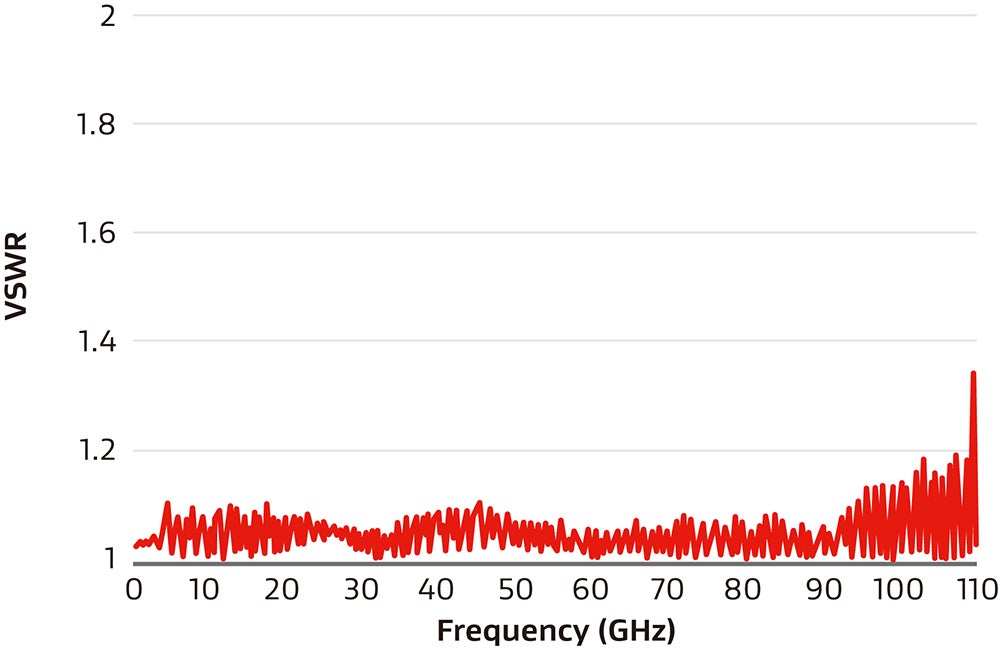

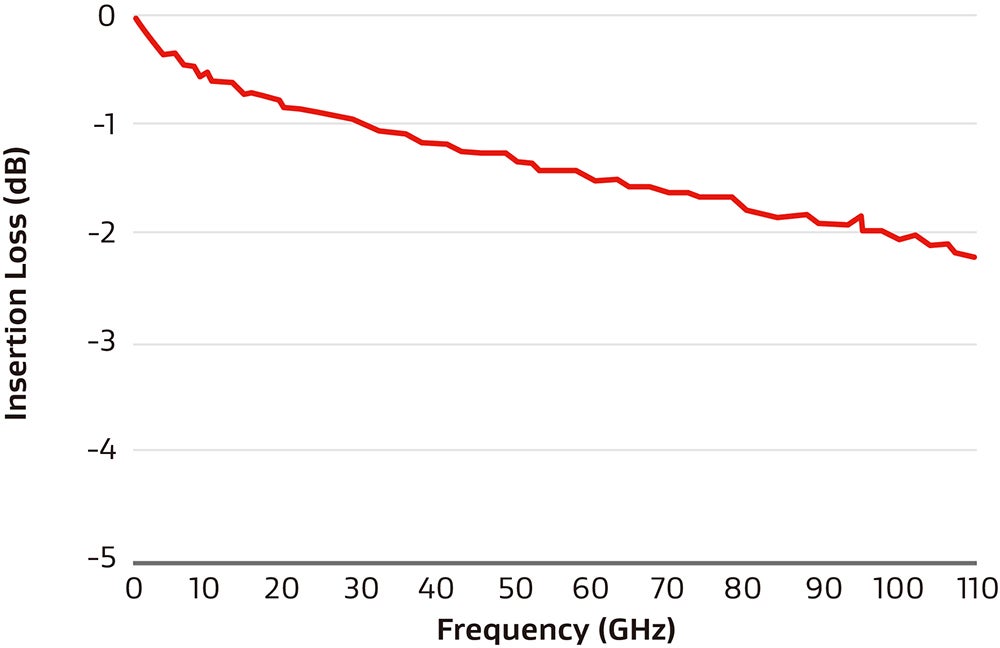

Our portfolio of GORE PHASEFLEX Microwave/RF Test Assemblies includes an 110 GHz version that can be flexed, formed, or repositioned without damage while providing excellent stability with flexure and temperature. These rugged, lightweight assemblies provide reliable electrical and mechanical performance in demanding environments for long service life. When tested, our 110 GHz test assemblies maintain low VSWR and insertion loss.

Typical VSWR and Insertion Loss of Gore’s 110 GHz test assemblies based on a 16 cm (6.3 in) assembly length.

Applications

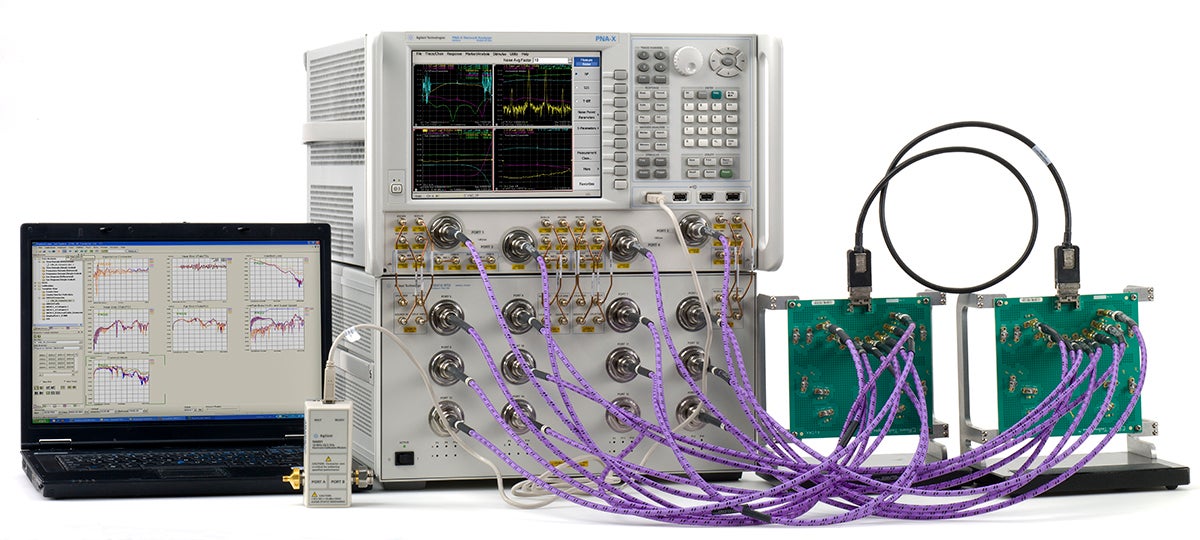

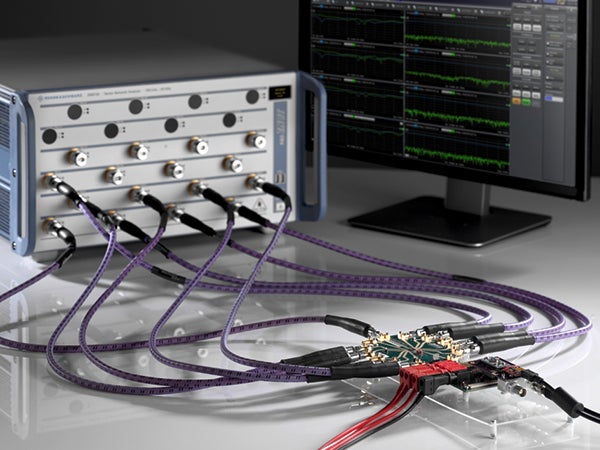

GORE PHASEFLEX Microwave/RF Test Assemblies are engineered to perform reliably in a variety of test and measurement applications, including:

Courtesy, Keysight Technologies, Inc.

Application on R&S®ZNBT Vector Network Analyzer.

Courtesy, Rohde & Schwarz GmbH & Co.

- anechoic chambers

- antenna ranges

- automated test equipment

- bench-top testing

- electromagnetic compliance testing

- high throughput RF production testing

- nearfield scanners

- portable analyzers

- scalar network analyzers

- test rack systems

- vector network analyzers (VNAs)

- wireless telecommunication module testing

- thermal vacuum chambers

- high speed digital test

- 5G test and interconnection

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Features & Benefits

GORE® PHASEFLEX® Microwave/RF Test Assemblies has been recognized among the 2020 Military & Aerospace Electronics Innovators Awards. Learn more

We have engineered features for GORE® PHASEFLEX® Microwave/RF Test Assemblies that make them more durable in demanding environments. Features include:

- torque, crush and kink resistance

- abrasion resistance

- dust and moisture resistance

- chemical resistance

- wide temperature range

- high connector pull strength

Our test assemblies provide manufacturers with many benefits that improve electrical and mechanical performance such as:

- consistent, repeatable measurements with stable electrical performance up to 110 GHz

- longer service life with durable construction that resists crushing, twisting and kinking

- enhanced phase and amplitude stability with flexure and temperature

- increased throughput and reduced downtime with durable and reliable performance

- a variety of connector options specifically engineered to optimize assembly performance

For more information about the features and benefits of our test assemblies, please contact a Gore representative.

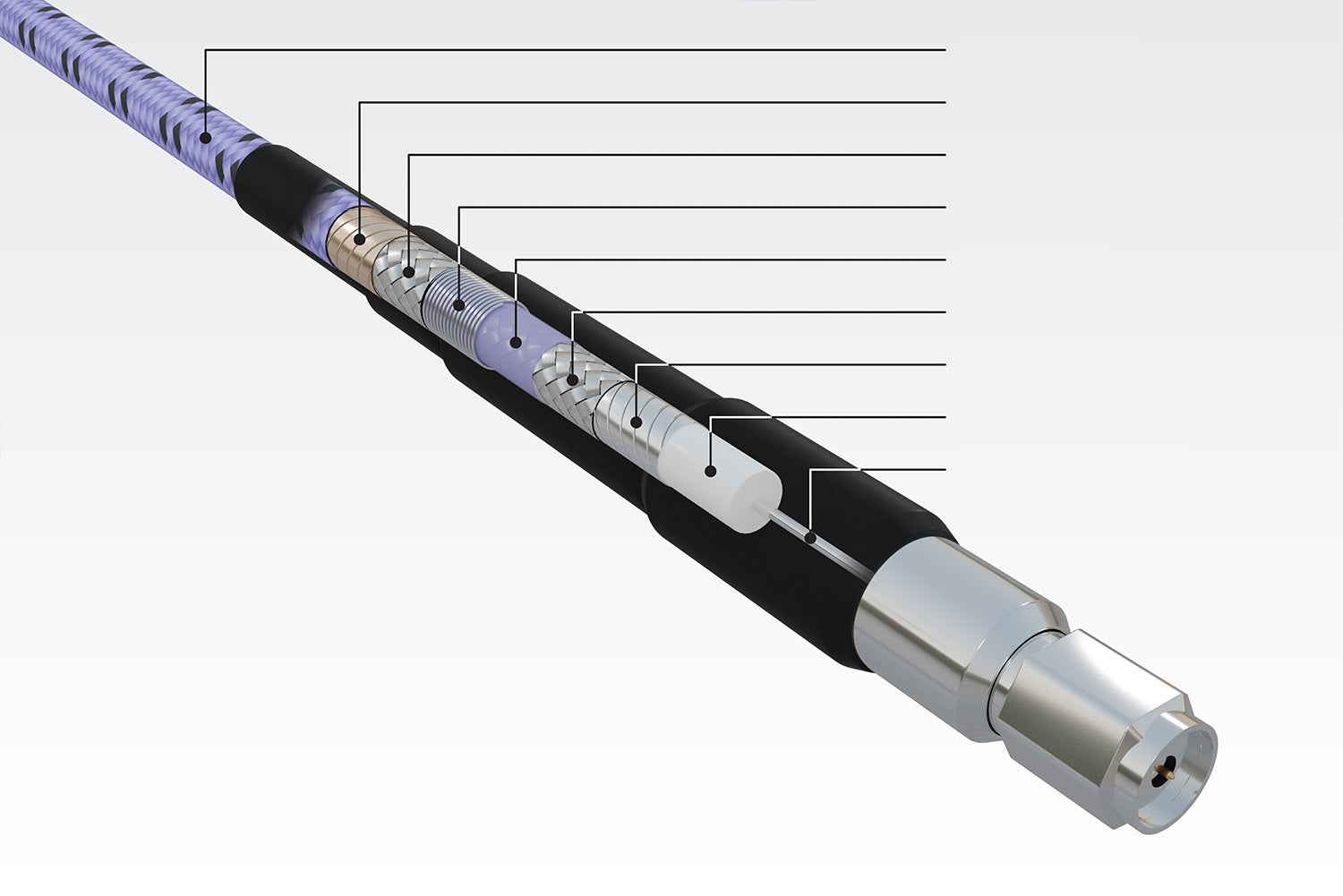

Construction of GORE® PHASEFLEX® Microwave/RF Test Assemblies

Properties

These values demonstrate the electrical, mechanical and environmental performance of our 110 GHz test assemblies.

Download the data sheet for more technical information, including comparison test data, connector options, and ordering information.

Electrical

| Gore Cable Type | CX |

|---|---|

| Maximum Frequency (GHz) | 110 |

| Typical VSWR | 1.34:1 |

| Typical Insertion Loss (dB) | 2.14 |

| Impedance (Nominal) (Ohms) | 50 |

| Typical Phase Stability (degree) | ±1.0 |

| Typical Amplitude Stability (dB) | < ±0.05 |

| Dielectric Constant (Nominal) | 1.6866 |

| Velocity of Propagation (Nominal) (%) | 77 |

| Shielding Effectiveness (dB through 18 GHz) | > 100 |

| Time Delay (Nominal) ns/m (ns/ft) | 4.33 (1.32) |

Mechanical and Environmental

| Gore Cable Type | CX |

|---|---|

| Center Conductor | Solid |

| Overall Diameter mm (in) | 4.2 (0.167) |

| Nominal Weight g/m (g/ft) | 55.8 (17) |

| Minimum Bend Radius mm (in) | 10.2 (0.40) |

| Temperature Range (˚C) | -55 to 125 |

| Crush Resistance kgf/cm (lbf/in) | 44.6 (250) |

Videos

Go to our YouTube Channel to watch these and other videos of Gore engineers demonstrating the benefits of GORE® Microwave/RF Assemblies.

Resources

Data Sheet: GORE® PHASEFLEX® Microwave/RF Test Assemblies

Data Sheets, 914.96 KB

Gore Product Selection Guide for 5G Test Systems

Product Selection Guides

Selecting Microwave/RF Cable Assemblies for Reliable Performance Over Time

White Papers, 5.48 MB

View all resources for PHASEFLEX Microwave/RF Test Assemblies

최신 뉴스

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

팔로우: GORE® PHASEFLEX® Microwave/RF Test Assemblies, 110 GHz