연대표에서

Browse through milestones in Gore's history.

2019

More Than 45 Million Patient Implants

Deliberate innovation to improve patient lives has driven us for more than 40 years – delivering more than 45 million patient implants worldwide since the medical division launched in 1975.

2018

Protecting Biologics

GORE® Improject Plunger unveiled. Provides the only option for silicone-free delivery of sensitive biologics.

2016

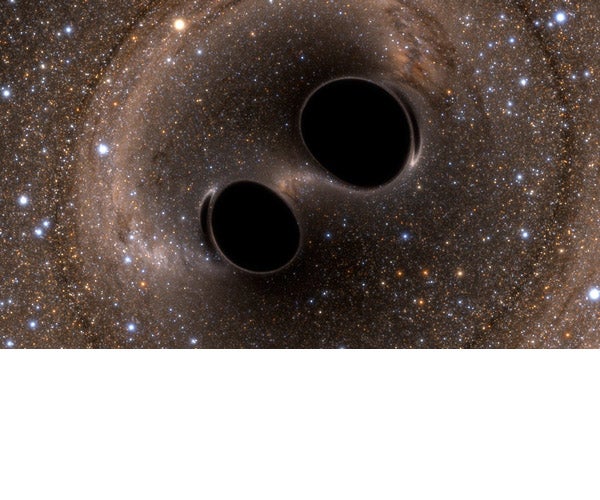

Assisting Astrophysics

GORE® High Flex Planar Cables played an important role in enabling astrophysicists in Italy and in the U.S. to detect gravitational waves, the existence of which were theorized by Albert Einstein nearly a century ago. This work earned the scientists the Nobel Prize in Physics in 2018.

2015

SHAKEDRY® for Runners and Cyclists

GORE-TEX Active with Permanent Beading featuring SHAKEDRY® Technology is the industry's first film-out jacket designed for the running and cycling markets.

2012

Enhancing Communication for Air Travelers

GORE™ Cable-Based Antennas are introduced to provide internet access to passengers aboard commercial airplanes.

2009

Ensuring a Good Game at Wimbledon

Architectural fabric woven from GORE® Fiber is used in the new retractable roof over Centre Court at London's Wimbledon tennis tournament.

2008

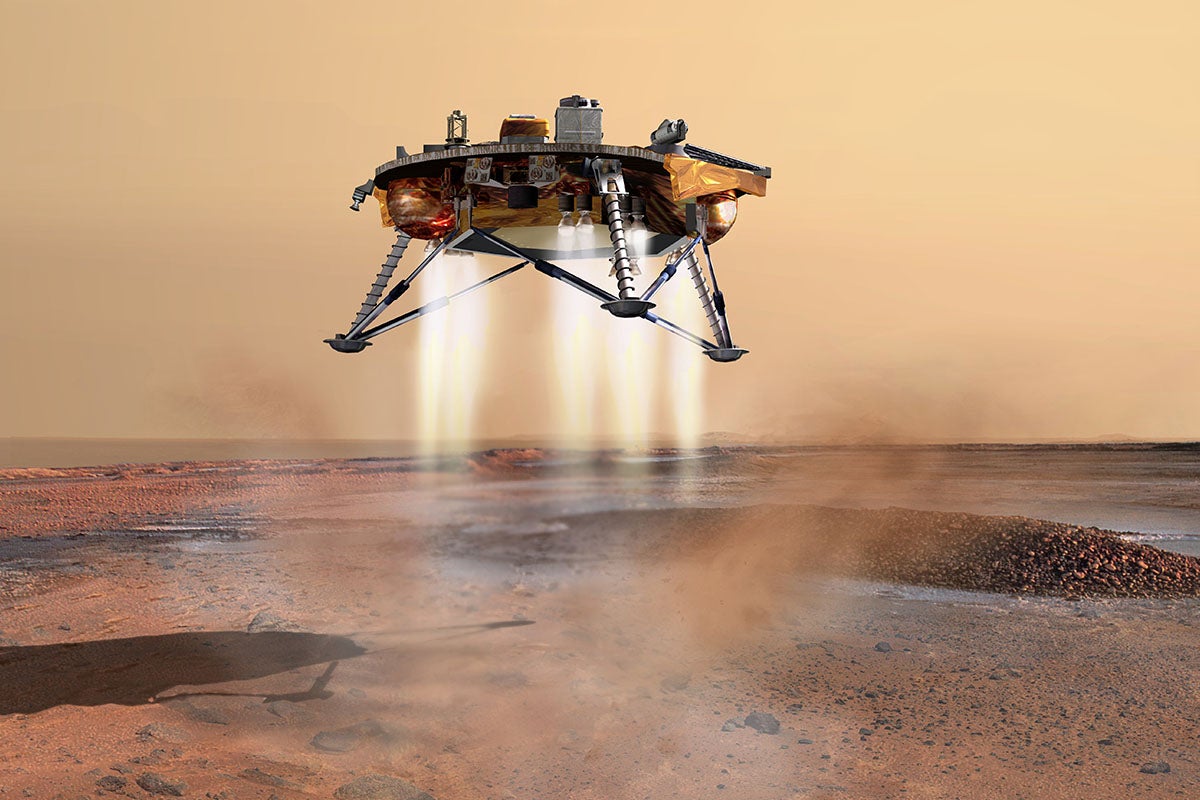

Contributing to Mars Exploration

NASA's Mars Phoenix Lander arrives safely on Mars. GORE® Spaceflight Microwave Cable Assemblies help to transmit data required for the spacecraft to position itself for landing.

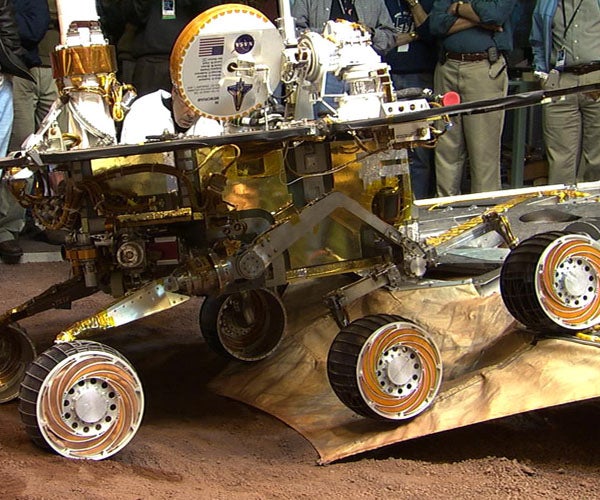

2004

Taking Photos in Space

Gore Microwave Cable Assemblies (GMCA) help NASA communicate with and receive pictures from the Spirit and Opportunity spacecrafts on Mars. Gore also supplied cable assemblies for the rovers' radiofrequency subsystems.

2001

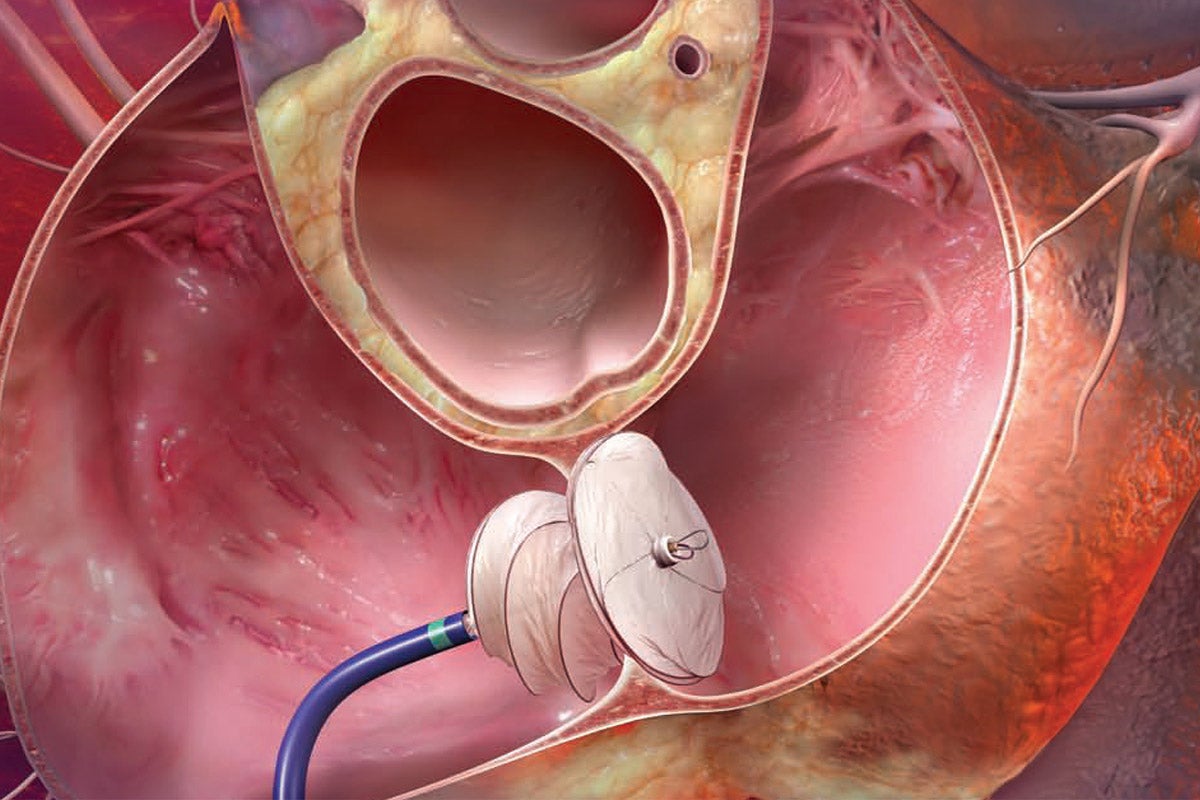

Mending Broken Hearts

The GORE® HELEX Septal Occluder, used to treat congenital heart defects, is launched in Europe, Africa, Australia and South America.

1997

Advancing Guitar String Technology

Gore introduces ELIXIR® Strings, which dramatically improve string tone life and reinvigorate the market for coated guitar strings.

Minimally Invasive Medical Technology

Gore introduces its first minimally-invasive endovascular prosthesis, marrying ePTFE grafts with Nitinol stents.

1995

Future of Fuel Cell Technology

Gore introduces a membrane electrode assembly used in fuel cell technology.

1994

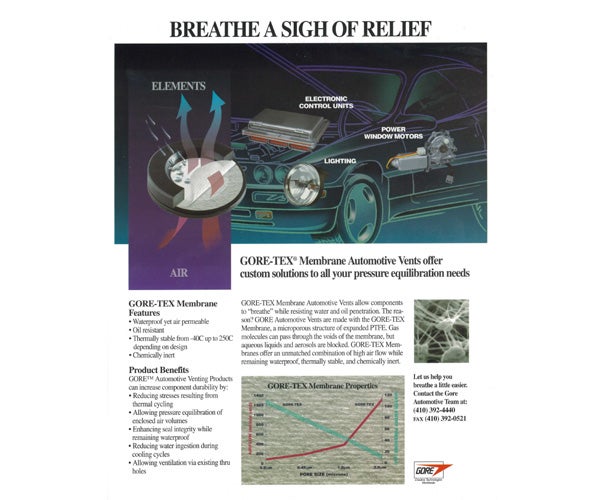

Automotive Vents for Superior Performance

Automotive vents using ePTFE offer superior performance in exterior and under-hood environments, allowing components to breathe while resisting water and oil.

1993

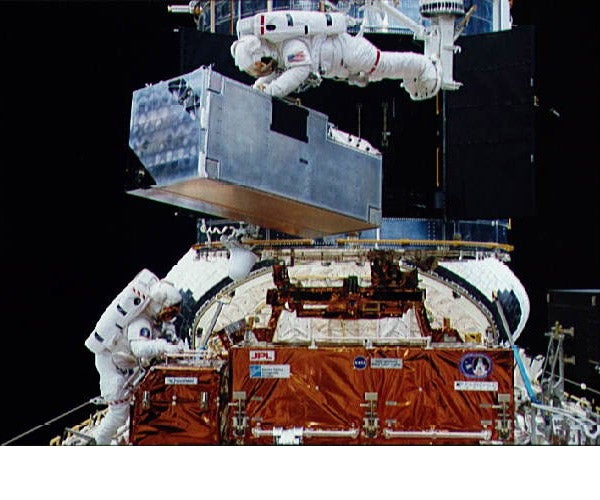

Equipping the Hubble Telescope

The COSTAR optics apparatus is developed for the Hubble Space Telescope with 11 sets of polyester insulated ribbon cable from Gore.

1990

GORE-TEX Fabrics Proven in Antarctica

An international team traversing the continent of Antarctica wears GORE-TEX Outerwear. One explorer credits the fabric with saving his life.

1988

Protecting Soldiers

Gore receives its first major orders for GORE-TEX Fabric for military personnel.

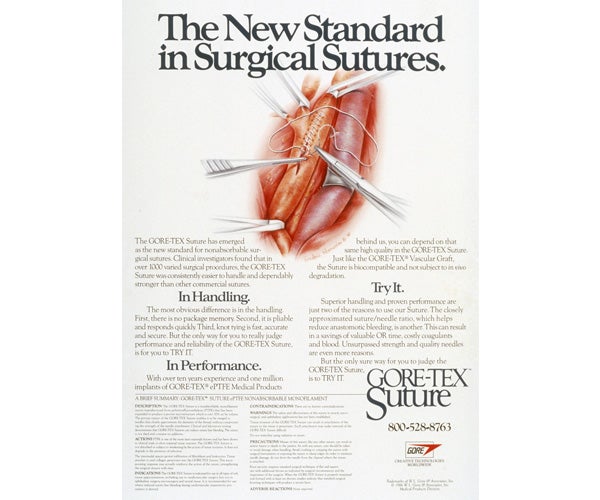

1986

Introducing ePTFE Sutures

GORE-TEX® Suture launches in the United States.

1981

Outfitting the Astronauts

Gore fiber is used in space suits designed for astronauts on the Columbia, NASA's inaugural space shuttle mission.

New Medical Applications Launch

Gore launches its first medical ePTFE patch product, the GORE-TEX® Cardiovascular Patch.

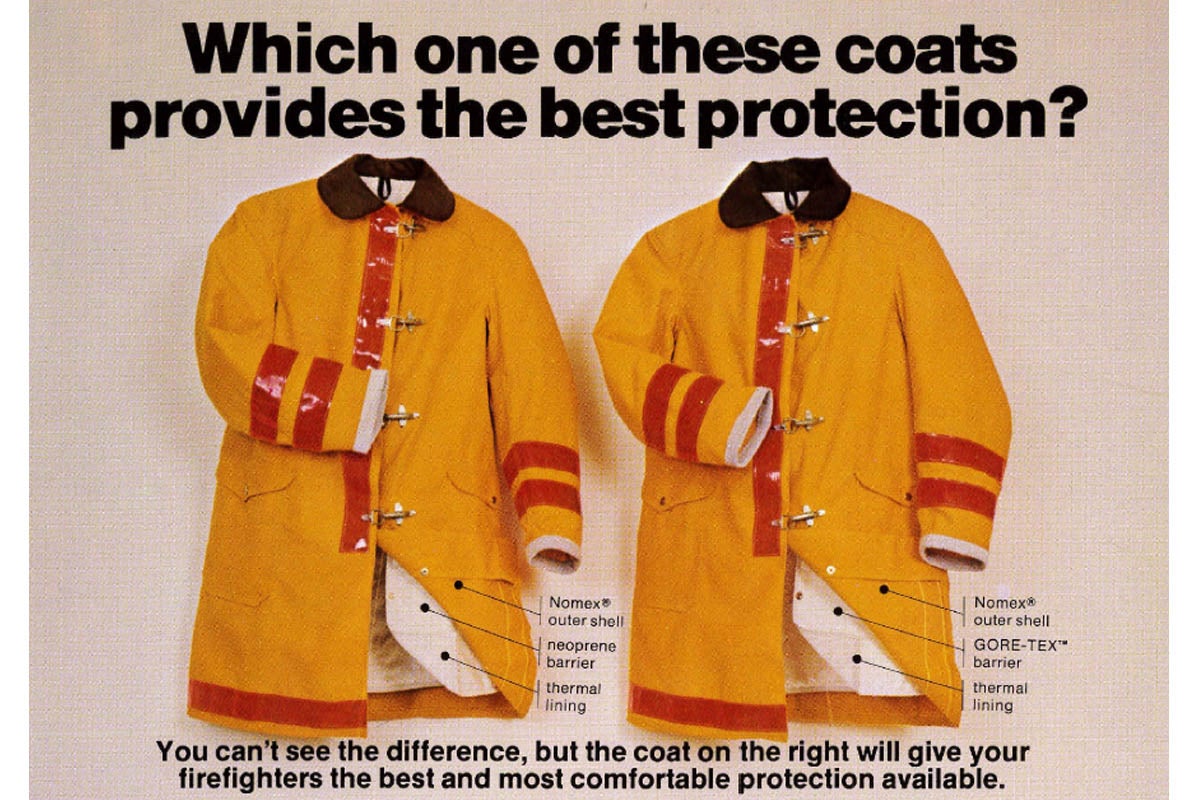

1980

Protecting First Responders

GORE-TEX® Barriers for firefighting turnout gear is introduced to protect first responders from excessive heat stress.

1976

GORE-TEX Fabric Launches

Gore makes its first sale of GORE-TEX Fabric to Early Winters, Ltd. catalog, which advertises its GORE-TEX Rainwear as "possibly the most versatile jacket ever made!"

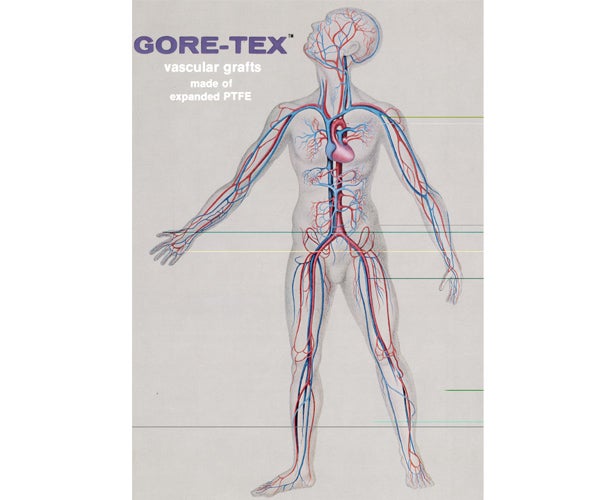

1975

GORE-TEX® Vascular Graft

The first GORE-TEX® Vascular Graft is commercialized, launching Gore's medical business.

1973

Cleaning the Air with Industrial Filtration

Gore's industrial filter bag business begins. Gore is the first to use expanded PTFE for filtration, pioneering membrane surface filtration to capture contaminants and other particles.

1970

ePTFE Improves Wire & Cable Products

New high-speed coaxial cables, the first commercialized applications of expanded PTFE in electronics, are introduced for the computer market.

1969

The Discovery of ePTFE

While experimenting with PTFE, Bob Gore stretches the material as rapidly as possible. Instead of breaking, as he expected, the expanded PTFE takes on new properties: strength, porosity and enhanced versatility. The watershed discovery dramatically expands Gore product offerings, opening the door to GORE-TEX Fabrics and other expanded PTFE products.

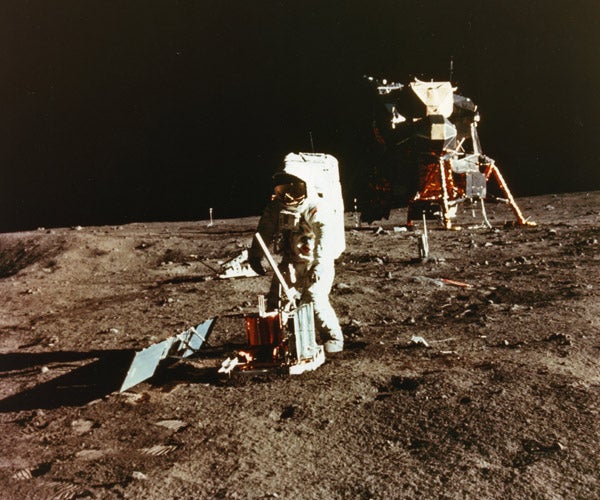

Courtesy of NASA

Products Land on the Moon

July 21: NASA’s Apollo 11 lands on the moon. Astronauts Edwin “Buzz” Aldrin Jr. and Neil Armstrong install seismographic equipment connected to the lunar lander with a small, lightweight cable manufactured by Gore.

1966

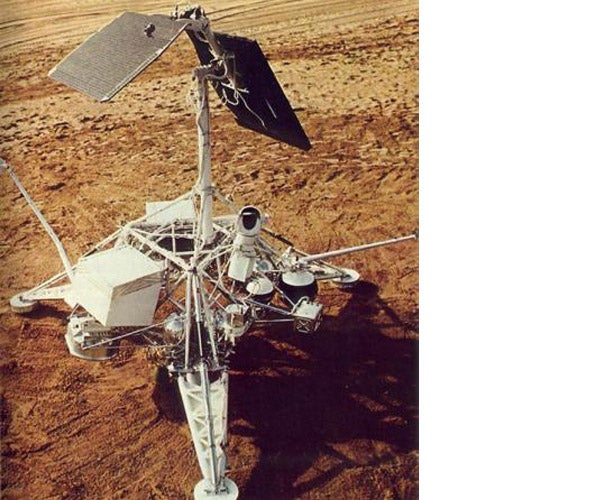

Courtesy of NASA

Supplying NASA

Gore supplies cable for NASA’s Surveyor missions, the first U.S. effort to make a soft landing on the moon.

1964

Courtesy of Creative Commons

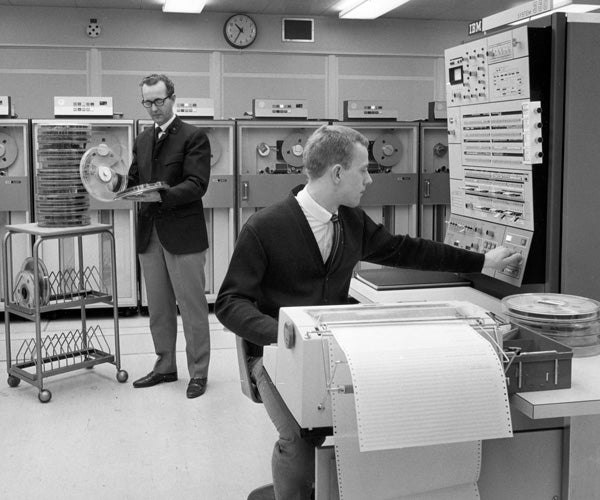

Groundbreaking Computer Relies on Gore Technology

Gore supplies cable for the groundbreaking and highly successful IBM System/360 mainframe computer, the first mass-produced digital computer. Gore is the sole supplier of the transmission lines interconnecting the system.

1963

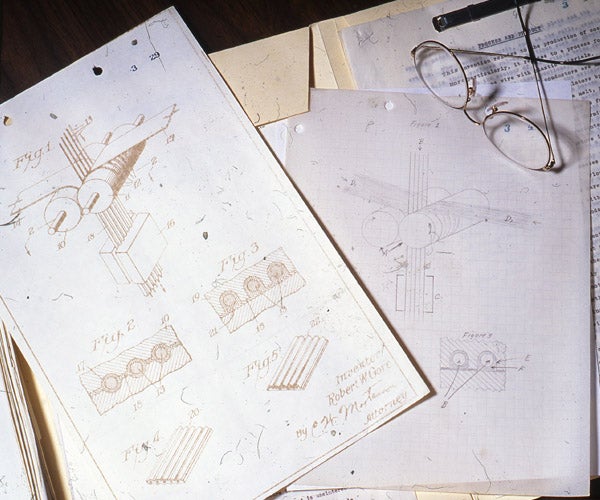

First Patent Awarded

The company earns its first patent. U.S. Patent 3,082,292 is issued to Bob Gore for the “Multiconductor Wiring Strip” known as MULTI-TET™ Cable. Bob Gore suggested this innovation to his father, Bill, while still a sophomore in college.

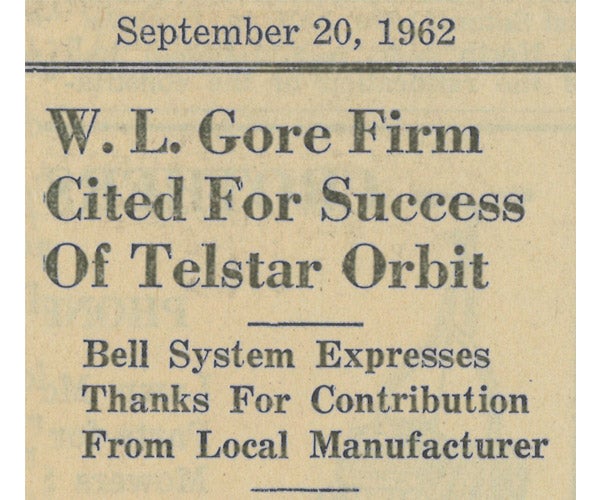

1962

First Products Used in Space

Gore cables are first applied in outer space on the Telstar satellite launched by Bell Laboratories.

1960

First Major Order is Received

The business remains focused on solving customer wiring problems with a variety of customized products and receives its first major order – 7.5 miles of insulated ribbon cable for the City of Denver.

1958

Founding an Enterprise

January 1: Wilbert L. (“Bill”) and Genevieve (“Vieve”) Gore launch W. L. Gore & Associates in the basement of their home in Newark, Delaware to pursue their belief in the untapped potential of the polymer polytetrafluoroethylene, or PTFE. The enterprise’s first product is MULTI-TET™ Insulated Wire and Cable. The ribbon cable will be used most heavily in aerospace applications and the burgeoning computer industry.